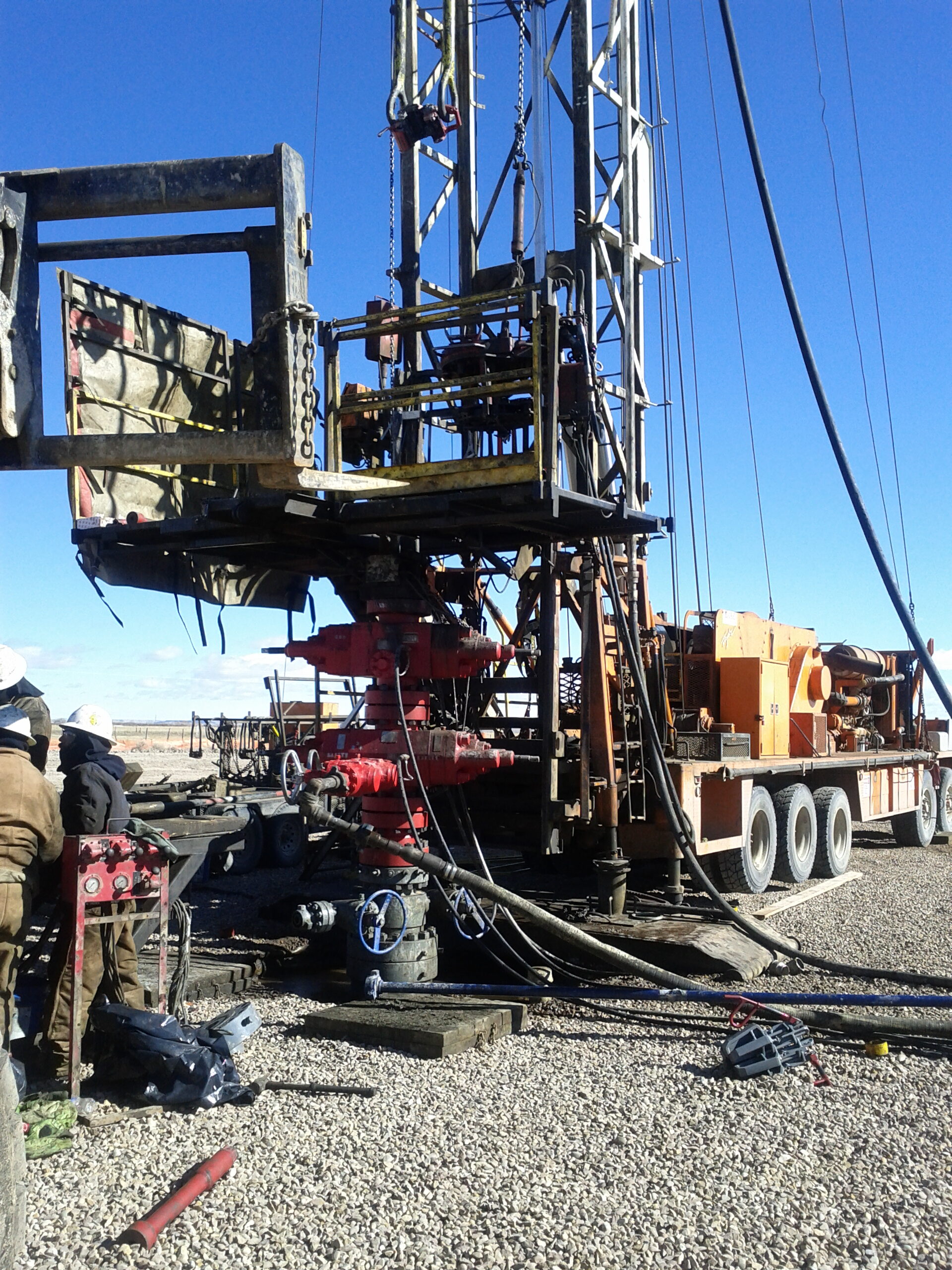

TECHNICAL SUPPORT & SERVICES

Blowout Preventer Verification & Testing

Our expert team conducts thorough routine inspections, rigorous functional tests, and meticulous pressure testing to certify that BOPs are ready to perform flawlessly in critical moments. Choose PCP Rentals for reliable, industry-leading BOP verification and testing that you can depend on.

Pre-Job Safety Meeting

Before testing procedures, PCP Rentals holds a meeting with everyone involved in the testing. During this meeting, we talk about how the testing will be done safely and what to do in case things don’t go as planned. We also check that all the tools and equipment we’ll be using are in good working condition. This meeting is important to make sure everyone knows what to do and that everything is ready for the testing to go smoothly.

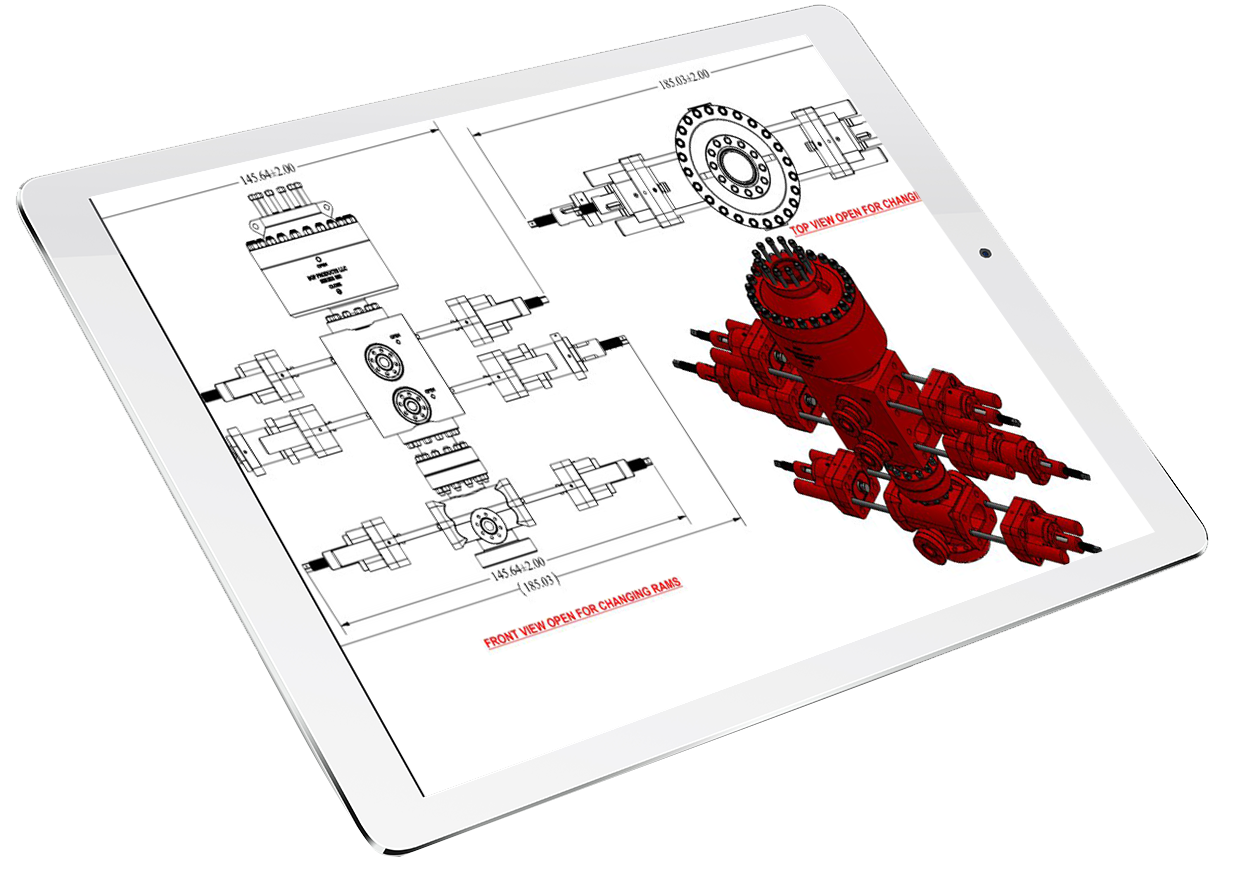

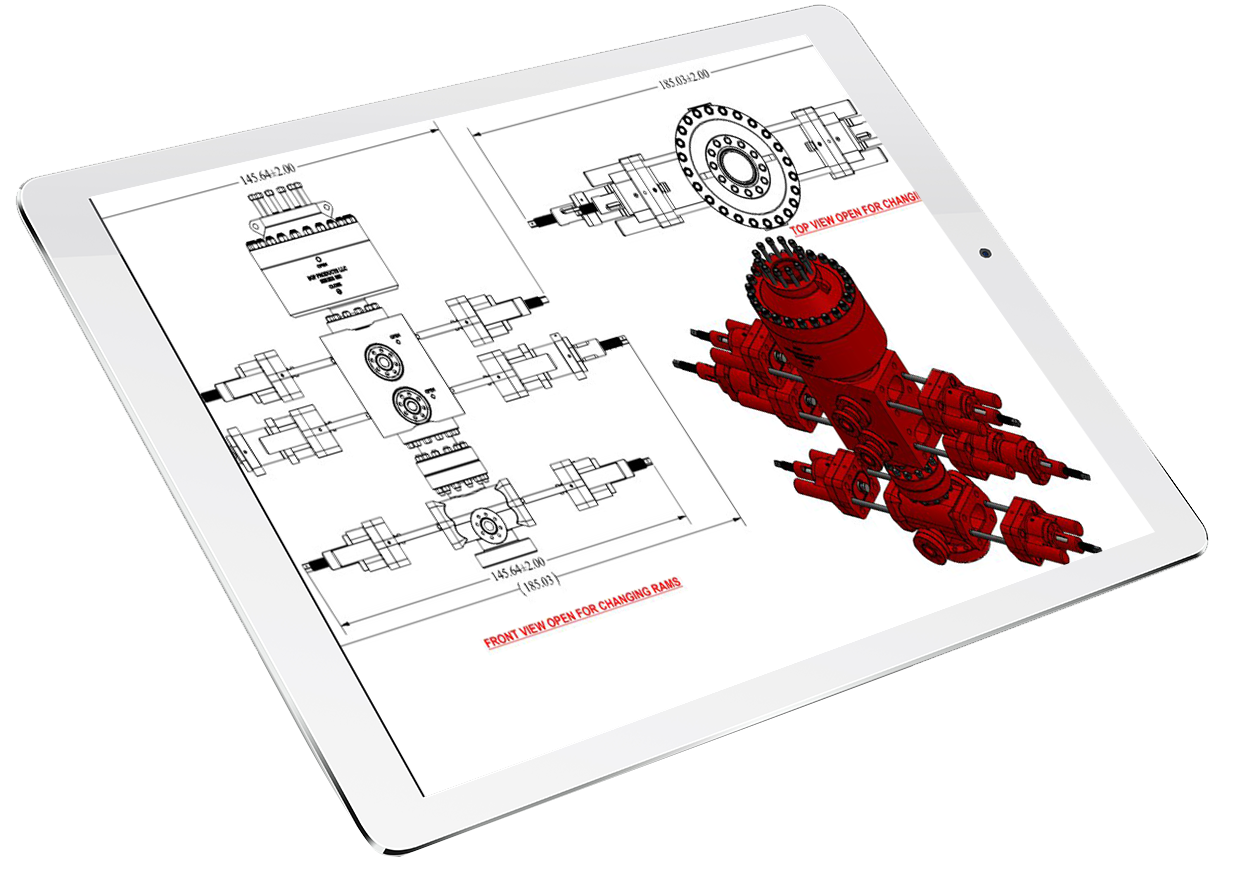

BOP Testing Procedures

- Ensure testing equipment is in calibration and all related equipment is in working condition.

- Pre-check accumulator system for proper pre-charge & pressure settings for BOPE in use & record.

- Ensure the correct specifications on the tubular being tested. (Labeled and order of test identified and MTRs are at the test site.)

- Ensure the shearing protocol is fully understood by the testing team with set objectives & deliverables.

- Ensure all OEM equipment is new and properly installed in the BOPE. (All serial numbers recorded for shear test equipment and internal components.)

- Confirm all safety barriers (tape or permanent fence, sirens, lights, bunker) are in place for high-pressure testing operations.

- Prepare camera for recording visual conformation of shear testing and clock to record time required to shear tubular.

- Prepare computer software for verification.

- All technicians and observers will have proper PPE if access to test area is required during shear testing operations.

- Discuss personnel responsibilities, identify potential hazards, and put contingencies in place.

Committed to Safety 24/7

Safety is a priority of everything we do, especially when it comes to guaranteeing safe field operations. It’s our goal to be your source for cutting-edge pressure control equipment that meets the strongest of standards.

Learn more about our commitment by viewing our comprehensive Health, Safety, and Environment (HSE) policy.

NEED MORE INFO?

Get in touch with our team for immediate assistance.

CONTACT US